Get the Grip on Green #5 – PET recycling process

RECYCLING PROCESS

You already know, that before our household waste can be recycled, it is collected and sorted.

Sorting means here for plastic packaging: By size, rigid packaging & flexibles, by polymer type and by colour. After this complex sorting process, the processing of the polymers follow. PET has two different recycling streams: clear & coloured. What kind of PET packaging is recycled, depends on the country.

Usually all PET bottles in clear or light blue are recycled. In some countries which have a deposit system, much more PET packaging like our Petpackers, can be recycled.

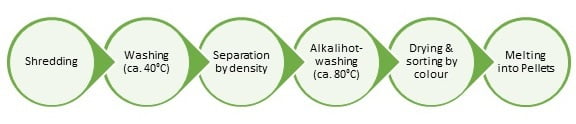

But how is PET usually processed during the recycling process? PET clear (after sorting out any coloured or opaque PET)

- Shredding: the material into small pieces

- Washing: a bath with circulating water (ca. 60-80°C) removes most residuals, labels and adhesives

- Separation by density: Different plastics are separated by different density, so one is sinking and the other is floating. PET has a density > 1 g/cm3, so it’s sinking. PE and PP have a density < 1 g/cm3, so it’s floating in water. The sank plastic is separated.

- Alkali hot-washing: Washing with alkali surfactants and water (ca. 85°C)

- Drying & colour sorting: the flakes will be sorted again, so only the clear PET stays

- Pellets: Flakes are further processed (melted) into pellets, that’s the clear PET-recyclate.

Why is the label & adhesive in combination with the container important for recycling?

The a. material & density, b. adhesive and c. print & size of the label are relevant for recyclability of the packaging.

a. The material & density:

Is important, because of the detectability and the density. E.g. a label made from PVC prevents the detection of the container material, because the NIR can’t detect through the PVC.

The result is, that the whole packaging can’t be sorted right and won’t be recycled. PET-G, the material of PET-labels, can’t be processed in the PET stream because of two reasons:

– Labels are printed, what means if this label ends up in a clear PET stream, it would contaminate the clear stream with inks. That lowers the quality of the recycled PET.

– PET-G can’t be re-melted under the same conditions as the PET which is used for rigid packaging. If a PET-label ends up in the re-melting step, it would destroy the entire batch, because it would burn during the melting. This is the same case for PLA labels.

Paper labels are not optimal, but if they are used they have to be as small as possible (<50% of packaging surface) and have to had a water soluble adhesive.

For a PET-container, every material which has a density < 1 g/cm3, e.g. PE, PP/ OPP is usually acceptable, as long as the following points are respected.

b. The adhesive

is important, because if the adhesive of the label is not water soluble, it can’t be removed from the packaging. It might remain on the shredded flakes and can effect a discolouration of the PET-recyclate, which can’t be further used then. Water- or alkali-soluble adhesives suitable for PET recycling should be used (adhesives are listed by PETcycle & EPBP).

c. Print & size of the label

Even if all parts of the packaging are fit for recycling, the print and size of the label can influence the detectability. E.g. if a label is too thick or the print doesn’t allow the NIR-light to pass the label, the container material can’t be detected. This causes a wrong sorting and avoids recycling or disturbs other streams because of contaminations. Metallised labels are usually not acceptable, because they reflect the NIR-light, which avoids a detection of the container material.

So, it would be the right way to let the detectability check by a recycling institute to prove it.

How is the quality of the recycled PET?

Some conditions are impacting the quality of the recycled material. Which causes, that each batch has a different quality:

- Colour: Currently, only clear PET has a valuable recycling stream, because a lot of applications can be made out of clear rPET. Sometimes transparent light-blue is accepted as well. It can be used to bring in a blue tint which helps the clear PET to appear more pure. Coloured or opaque PET is declared as not recyclable, because there are no valuable applications for recycled coloured PET in the market yet. The clear rPET has a different colour than the virgin one. During the mechanical recycling process, the polymer is mechanically strained, which causes some changes of its character. One by-effect is the colour change. Another reason might be that during the process, some other coloured PET flakes end up in the clear PET stream, which causes discolouration.

- Processing: Sometimes it is necessary to adapt production processes for recycled materials, because it is already strained. The mechanical recycling process downgrades the material slightly. That’s why plastics are not endless recyclable, but at least a few times. The recyclate won’t be used anymore, when it gets a poor quality, that means changed material properties, contaminations, etc.

- Food-grade: rPET can have food-grade. It’s currently the only recycled material with food-grade. At Pont, we are only offering food-grade rPET in our products. Source of food-grade rPET: It comes from the deposit beverage bottles, e.g. from the Netherlands or Germany, which has a separate recycling circle. Other rPET sources with food-grade are currently not available. Only EFSA (European Food Safety Authority) approved recycling processes are allowed in the market and they contain max. 5% of non-food (packaging) material in food-grade rPET.

Aufgrund der raschen Entwicklung der Nachhaltigkeit in der Verpackungsbranche sowie lokaler Unterschiede bei Recyclingprozessen und Gesetzen dienen die in diesem Dokument enthaltenen Informationen nur zur Information.

Wir empfehlen Ihnen, das Update Ihrer örtlichen Vorschriften zu überprüfen.